Los Angeles and Orange County HP LaserJet 8000 Printer Repair and Laser-jet 8000 Maintenance Service Error Code Repairs Los Angeles, Orange County, San Bernardino Ca!

Same Day onsite Laser-Jet 8000/8000n repair and service in Southern California!

We specialize on HP LaserJet 8000 printer repair and onsite printer service in Los Angeles and Orange County with image defects, vertical lines, horizontal lines, repeating dots, error messages, error codes, and maintenance errors. We provide LaserJet 8000 printer series HP 8000, 8000n and 8000dn printer repair with 57 fan error, Error 50, 50.1, 50.2 fuser errors. Our LaserJet 8000 printer service team has the technical ability to provide Laser-Jet 8000 series printer repair on the first visit.

Every Hewlett Packard Laser Jet 8000 printer repair/service includes a free cleaning by HP Certified technicians. Our HP LaserJet 8000 service team carry printer repair parts and have the technical ability to fix your laser printer on the first visit. We are experts at solving HP LaserJet 8000 print defects with vertical lines, Horizontal lines, smeared prints, not bonding toner on the paper, dirty printing, repeating images and dots.

We carry HP LaserJet 8000 Fuser Unit, LaserJet 8000 Maintenance Kit, Roller Kits, 8000 paper cassette trays, Registration Assembly for HP laser jet 8000, Transfer Roller, Pickup assembly for HP LaserJet 8000 series printer, HP Laser 8000 Duplex unit, HP LaserJet 8000 Formatter PCA, DC Controller and tray 1 Assembly for HP LJ 8000 series printers.

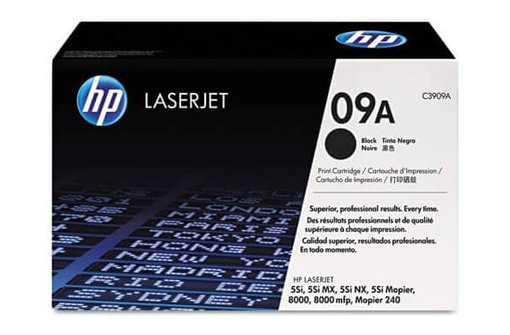

We Sell Original HP LaserJet C3909a Toner Cartridge Can Be Used in 5si, 5si Mx, 5si Mopier and HP Laserjet 8000 Series Printer.

The HP 09A Black LaserJet Toner Cartridge is ideal for medium-to-high-volume business users. It has been designed together to work together with the HP LaserJet 5si, 5si MX, 5si mopier printer and LaserJet 8000 printer series. The high-capacity, long-lasting cartridges offer an approximate cost-per-page of one penny, with fewer replacements and less downtime. Average cartridge yields 15,000 standard pages.

Hewlett Packard Laserjet 8000 Printer Repair with 13 Paper Jam Error Codes!

- HP LaserJet 8000 13.0 paper jam. The printer detects a paper jam immediately after the printer is turned on

- LaserJet 8000 13.1 errors messages indicate that the paper did not leave Tray 2 or Tray 3.

- Hewlett Packard LaserJet 8000 13.2 errors indicate that the paper did not reach the sensor located under the toner.

- LaserJet 8000 13.3 error code indicate a crumpled paper under the print cartridge or registration

- Laser Jet 8000 13.4 error message indicate that the paper did not reach the sensor located in the fuser.

- HP LJ 8000 13.5 error messages indicate that the paper has not reached the upper output bin.

- HP laser 8000 13.6 error code indicate that paper has stopped on the way to the upper output bin.

- Laser Jet 8000 13.7 errors indicate that the paper never reached the first sensor in the duplexer.

- HP 8000 13.8 error indicate that the paper made it into the duplexer, but stopped or jammed while being flipped.

- 8000 13.10 errors indicate that the paper has stopped over the last sensor in the duplexer.

- Hewlett Packard 8000 13.11 error messages indicate a problem exists with Tray 4.

- HP 800013.12 error messages indicate there is a problem with the Multi-Bin Mailbox.

Hewlett Packard Laser-jet 8000 Printer Model (c4085a)

- HP Laser Jet 8000 Res Enhancement 1200 x 1200 DPI

- 8000 Printer Speed 24 PPM (17 seconds first page out)

- Wide Format (11.7″ x 17.7″)

- 16 MB Memory (expandable to 192 MB)

- Laser-Jet 8000 Connects Via Parallel

- PostScript Level 2 Emulation

HP Laser Jet 8000n Printer Specification (c4086a)

- HP Laser-Jet 8000 Resolution 1200 x 1200 DPI

- HP 8000 Printer Speed: 24 PPM (17 seconds first page out)

- HP 8000 printer, Prints in Wide Format (11.7″ x 17.7″)

- LaserJet 8000 Network Ready (10/100 BaseTX)

- 16 MB Memory (expandable to 192 MB)

- laserjet 8000 Connects Via Parallel and Fast Ethernet

- 8000 printer PostScript Level 2 Emulation

HP Laser Jet 8000dn Printer Specification (c4087a)

- Laser-jet 8000 Resolution 1200 x 1200 DPI

- HP 8000 prints at 24 PPM (17 seconds first page out)

- Wide Format (11.7″ x 17.7″)

- Network Ready (10/100 BaseTX)

- Auto Duplex Unit (Double Sided Printing)

- 8000 Laser Printer: 24 MB Memory (expandable to 192 MB)

- 8000 printer connects Via Parallel and Fast Ethernet

- HP Laser Jet 8000 PostScript Level 2 Emulation

Laserjet 8000 Service Error Code Repairs in Los Angeles, Orange County & San Bernardino!!

Hewlett Packard 8000 printer repair technicians will resolve hardware failures and service error codes!

| HP 8000 Error Messages | HP LaserJet 8000 Recommended Action |

| ACCESS DENIED MENUS LOCKED | The printer control panel function that you are trying to access has been locked to prevent unauthorized access. See your network administrator. |

| BAD DUPLEXER CONNECTION | The duplexer is not connected properly. Reinstall the duplexer. |

| CHECK INPUT DEVICE alternates with PAPER PATH OPEN PLEASE CLOSE IT | The optional input tray cannot feed paper to the printer because a door or paper guide is open. Check the doors and paper guides. |

| CHECKING PAPER PATH | The engine is rolling its rollers to check for possible paper jams. |

| DISK DEVICE FAILURE | A print job requested a printer language that does not exist in the printer. The job will not print and will be cleared from memory. Print the job using a driver for a different printer language or add the requested language to the printer (if available). Press GO to continue. |

| CHOSEN LANGUAGE NOT AVAILABLE | The EIO disk had a critical failure and can no longer be used. Remove the EIO disk and replace it with a new one. |

| DISK FILE SYSTEM IS FULL | The requested operation could not be performed. You might have attempted an illegal operation, such as trying to download a file to a nonexistent directory. |

| DISK IS WRITE PROTECTED | Delete files from the EIO disk and then try again. Download or delete files from HP Jet admin and download or delete fonts from HP Font Smart. |

| DISK FILE OPERATION FAILED | The EIO disk is protected, and no new files can be written to it. Disable the write protection through HP Jet-admin. |

| EIO DISK INITIALIZING | The disk accessory card takes a long time to initialize. The first parameter (n) is the accessory slot number for this disk accessory card. |

| EIO n DISK NOT FUNCTIONAL | The EIO disk is not working correctly. |

| EIO n INITIALIZING alternates with DO NOT POWER OFF | Wait for the message to disappear (approximately five minutes). If the printer EIO card is operating correctly and communicating with the network, this message disappears after approximately one minute, and no action is required. If the EIO card is unable to communicate with the network, this message remains for five minutes and then disappears. In this case, the printer is not communicating with the network (even though the message is no longer present). The problem may be a bad EIO card, a bad cable or connection on the network, or a network problem. Contact your network administrator |

| EIO n DISK SPINNING UP | The disk accessory card takes a long time to initialize. The first parameter (n) is the accessory slot number for this accessory card. |

| Env feeder load [Type] [Size] | Load the requested envelope type and size into the envelope feeder. Make sure that the envelope size and type are set correctly from the Paper Handling Menu in the printer’s control panel. |

| Memory storage page simplified | The printer had to compress the job in order to fit it in available memory. Some data loss might have occurred. |

| OFFLINE | Press the go key to place the printer online. |

| Output bin full clear (Bin nnn) (nnn=bin name) | The output bin is full and needs to be emptied. If problem presist the output bin sensor is stuck |

| Perform Printer Maintenance | To ensure optimum print quality, the printer prompts you to perform routine maintenance every 350,000 pages. |

| RAM DISK DEVICE FAILURE | The RAM disk had a critical failure and can no longer be used. Turn the printer off and then turn the printer on to clear the message. |

| RAM DISK FILE OPERATION FAILED | The requested operation could not be performed. You might have attempted an illegal operation, such as trying to download a file to a nonexistent directory. |

| RAM DISK FILE SYSTEM IS FULL | Delete files and then try again, or turn the printer off and then turn the printer on to delete all files on the device. (Delete files using HP Jet admin, HP Font Smart, or another software utility. See the software help for more information.) |

| TONER LOW | The print cartridge is running out of toner. Redistribute toner in the print cartridge or install a new print cartridge. |

| TRAY x EMPTY | Load the empty tray (x) to clear the message. If you do not load the specified tray, the printer will continue printing from the next available tray, and the message will continue to display. |

| Message 13.59.11 | A paper jam occurred at Vertical Transfer Assembly exit or after opening the Vertical Transfer Assembly. Paper in PS32 (see Figure 7-14) at power-on (flush routine not implemented at power-on). If Error Log Message 13.59.1y is followed by 66.00.19 or 66.00.20 in the printer’s error log, this means the printer was printing a long job and a time-out occurred |

| Error Message 13.01.12 | A paper jam occurred at the Flipper Assembly’s input (refer to Figure 7-17). The flipper assembly is located in the upper portion of the Multi-Bin Mailbox; the assembly receives paper from the printer via the Input Paper Guide and directs paper into either the face-up bin or into the transport belt of the mailbox. PSEntry detects paper entering the Flipper Assembly. NOTE: Power off the printer. Position the mailbox away from the print engine. Hold down the mailbox interlock (refer to Figure 7-12, callout 3). Then power on the printer. The mailbox goes through its normal power-on sequence (the head assembly in the mailbox moves to the bottom-most position on the mailbox, then travels up to its home position). Any fault condition in the mailbox prevents it from going through its normal power-on, full down and up sequence. |

| Error Message 13.02.22 | A paper jam occurred at the Face-Up Bin (output of the Flipper Assembly). The Flipper Assembly, located in the upper portion of the Multi-Bin Mailbox, receives paper from the printer via the Input Paper Assembly (refer to Figure 7-20). The assembly directs paper to either the Face-Up Bin or to the mailbox’s transport belt. PSFaceUp sensor flag detects paper as the paper moves from the Flipper Assembly into the Face-Up Bin |

| Error Message 13.03.32 | A paper jam occurred along the Transport Belt. When the paper’s final destination is either the stapler or one of the mailboxes, paper moves from the Flipper Assembly to the Transport Belt. Magnetic attraction holds the paper between the transport belt and a magnetic strip affixed to the moving head assembly |

| Error Message 13.04.42 13.05.52 | A paper jam occurred in the delivery head. The delivery head receives paper as it moves down the Transport Belt. The delivery head delivers paper to either the designated mailbox slot or to the stapling assembly. The PSExit 1 photosensor flag detects paper as it enters the delivery head (refer to Figure 7-18). Once paper is sensed, the eject motor rotates and moves paper to the bin. The PSExit 2 photosensor flag detects the paper’s trailing edge as it moves from the head assembly into the designated bin |

| Error Message 13.06.62 | A paper jam occurred on the delivery head (while scanning for bins). During power-on, the Multi-Bin Mailbox and the delivery head travels the length of the mailbox verifying that all bins (and the stapler) are installed. This is performed when the PS Bin Full/Head Position photosensor, located in the delivery head assembly, reads a “scan bar”. The scan bar is formed by plastic protrusions located on the rear surface of each bin and the stapling assembly. |

| Error message 13.11.03 | Clear any paper from the stapling bed: Open the top cover assembly. Inspect the offset and registration pusher arms. Verify that nothing interferes with their movement. You should be able to easily slide the arms back and forth with a slight amount of resistance. Remove any obstruction(s). Cycle power. See if the printer completes its power-on sequence. Check the top cover assembly pushers and cables. If the pushers are stuck or the cables are damaged, replace the entire assembly. The top cover assembly includes the cables. Replace the entire stapling unit as required. |

| Error Message 13.12.03 | To remove the paper on the stapling bed: Cycle power. See if the stapler completes its power-on sequence (see Error Log Message 13.11.03). Determine if the wire bail on the stapler’s output paper path is not installed upside down. The stapler’s sliders should not hit the bail. Check the stapling bed assembly, which includes the sliders and cables. If the sliders are stuck or the cables are damaged, replace the entire stapler. |

| Error message 13.13.03 | To clear the retainer jam: Remove the stapling assembly. Inspect the retainer fingers to determine if anything is preventing them from rotating. Remove any obstructions that may be present. Remove the stapling assembly’s back plate (refer to Figures 6-88 and 6-89). Verify that the Retainer Motor connect is connected to the Control PCA (refer to callout 2 on Figure 6-91). If all connections are secure on the Control PCA, yet the retainer fingers are still “stuck,” replace the stapling assembly. |

| 20 INSUFFICIENT MEMORY | The printer received more data than can fit in its available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. |

| 21 PAGE TOO COMPLEX | The data (dense text, rules, raster, or vector graphics) sent to the printer was too complex. Press GO to print the transferred data. (Some data might be lost.) To print the job without losing data, from the Configuration Menu in the printer control panel, set Page Protect=On, print the job, and then return Page Protect=Auto. Do not leave Page Protect=On; it might degrade performance. |

| 22 EIO x BUFFER OVERFLOW | Too much data was sent to the EIO card in the specified slot (x). An improper communications protocol may be in use. Press GO to clear the message. (Data will be lost.) |

| 22 PARALLEL I/O BUFFER OVERFLOW | Too much data was sent to the parallel port. Check for a loose cable connection and be sure to use a high quality cable. (Some non-HP parallel cables might be missing pin connections or might otherwise not conform to the IEEE-1284 specification.) This error can occur if the driver you are using is not IEEE-1284 compliant. For best results, use an HP driver that came with the printer. |

| 41.3 UNEXPECTED PAPER SIZE | The paper size on which you are trying to print is not the same as the control panel setting for Tray 1. Make sure that control panel setting for Tray 1 or the envelope feeder is correctly adjusted for size. (The printer will continue trying to print the job until size settings are correct.) |

| 41.x PRINTER ERROR | A temporary printing error occurred. Press GO. The page containing the error will automatically be reprinted. |

| Service Message 50.1, 50.2, 50.3 and 50.4 fuser error. | Service error 50.01 Fuser low temperature failure. Error 50.02 Warm-up failure. 50.03 over temperature failure. 50.04 Bad fuser |

| Message 51.01.00 x = 1: Beam detect malfunction x = 2: Laser malfunction | Press [Select] to resume operation. NOTE: If the printer is set to AUTO CONTINUE=ON, the printer will automatically continue printing when this error occurs. If error persists, reseat or replace cables from the DC Controller to the Laser/Scanner Assembly. Replace the Laser/Scanner Assembly. Replace the DC Controller PCA. |

| Service Message 52.01.00 52.02.00 Scanner Failure | A scanner subsystem problem exists. 52.01 Scanner start-up failure, 52.02 Scanner rotation failure |

| 53.xy.zz Printer Error | There is a problem with the printer’s memory. The DIMM that caused the error will not be used. Values of x, y, and zz are as follows: x = DIMM type 0 = ROM 1 = RAM y = Device location 0 = Internal memory (ROM or RAM) 1 to 3 = DIMM slots 1, 2, or 3 zz = Error number You might need to replace the specified DIMM. Turn the printer off and then replace the DIMM that caused the error. |

| 55.xx Printer Error alternates with Press go to continue | A temporary printing error occurred. Press the GO. The page containing the error may automatically be reprinted. 2. Turn printer off, unplug it and reseat the formatter board. If error returns, turn the printer off and remove all DIMMS, EIO Cards, Hard Disk Drive |

| 57.1 fan error, 57.2 fan failure, 57.3 stalled fan, 57.4 freeze fan | A fan motor failure occurred (refer to Figure 7-3). All fans are enabled to low speed operation at printer power-on. Fans will go into high-speed operation during the print cycle. All fans are disabled during PowerSave Mode. 57.1 error FM1-bad Laser/Scanner Fan, 57.2 error FM2-Power Supply Cooling Fan failure, 57.3 error FM3-Formatter Fan failure and 57.4 error FM4- Face Down Deliver Fan failure. |

| Service Message 58.01.00, 58.02.00, 58.03.00 and 58.04.00 | 58.1 = Tray 2 lifter malfunction 58.2 = Tray 3 lifter malfunction 58.3 = Tray 1 lifter malfunction 58.4 = Tray 4 lifter malfunction |

| Service Message 59.01.00 and 59.02.00 | The Main Motor is powered by +24VB, which is generated when Switch 1401 on the Switch/Sensor PCA closes. 59.1 = Main motor start up failure and 59.2 = Main motor rotation failure. |

| 62.x PRINTER ERROR | There is a problem with the printer’s memory. The x value refers to the location of the problem: 0 = Internal memory 1 to 3 = DIMM slots 1, 2, or 3 You might need to replace the specified DIMM. |

| 64.x PRINTER ERROR | A temporary printing error occurred. Turn the printer off and then turn the printer on. |

| 66.xy.zz INPUT DEVICE FAILURE | An error occurred in an external paper-handling device. Turn the printer off and then turn the printer on. |

| 68 NVRAM ERROR CHECK SETTINGS | An error occurred in the printer’s nonvolatile memory (NVRAMAn error occurred in an external paper-handling device. Turn the printer off and then turn the printer on. Print a configuration page and check the printer settings to determine which values have changed. Hold down Cancel Job while turning the printer on. This will clean up the NVRAM by removing old areas that are not being used. |

| 68 NVRAM FULL CHECK SETTINGS | The printer’s nonvolatile memory (NVRAM) is full. Some settings might have been reset to the factory defaults. Print a configuration page and check the printer settings to determine which values have changed. |

| 69.x PRINTER ERROR | A temporary printing error occurred. Turn the printer off and then turn the printer on. |

| 79.xxxx PRINTER ERROR | The printer detected an error. The numbers (xxxx) indicate the specific type of error. Turn the printer off and then turn the printer on. Try printing a job from a different software application. If the job prints, go back to the first application and try printing a different file. (If the message only appears with a certain software application or print job, contact the software vendor for assistance.) |

| 8x.yyyy CRITICAL ERROR (EIO accessory) | The EIO accessory in slot x has encountered a critical error as specified by yyyy. x = Description 1 = EIO slot 1 – The printer detected an error with the EIO card. 2 = EIO slot 2 – The printer detected an error with the EIO card. 6 = EIO slot 1 – The EIO card detected an error. 7 = EIO slot 1 – The EIO card detected an error. |

HP Laserjet 8000 Replacement Parts We Carry to Provide Fast Onsite Service in Southern California!

| HP LaserJet 8000/800n Part Descriptions | HP Laser Jet 8000 PART NUMBERS |

|---|---|

| HP LaserJet 5si Fixing Assembly/Fuser Unit | RG5-4447 |

| HP laser jet 5si Maintenance Kit | C3971-67903/ C3971-67902 |

| HP laserjet 5si Pickup Assembly, Tray 1 | RG5-1880 |

| HP 5si Tray 1 Pickup Roller | RB1-6730 |

| HP laser jet 5si Pickup Rollers Tray 2/3) | RF5-1835 / RF5-1427 |

| HP LJ 5si Feed Separation Rollers | RF5-1834 / RF5-1426 |

| HP laserjet 5si Delivery Assembly | RG5-1874-000 |

| HP 5si Transfer Roller | RG5-1887 / RF5-1412 |

| Laserjet 5si Laser Scanner Assembly | RG5-1895-050 |

| HP laserjet 5si Formatter PCA | C3168-67903 |

| HP laser-jet 5siPaper Pickup Assembly (Tray 2&3 | RG5-1852 |

| JetDirect 600N, EIO,Ethernet, 10BaseT | J3110A |

| HP laserjet 5si Registration Assembly | RG5-1833-000 |

| HP laserjet 5si Toner Cartridge C3909A-C3909X | C3909A |

| HP 5si Duplexer Assembly | C3762A |

| Laserjet 5si DC Controller | RG5-1844 |